Preventing Weld Undercut Demystified: Techniques for Success

Preventing Weld Undercut Demystified: Techniques for Success

Blog Article

Mastering the Art of Welding: Just How to Avoid Undercut Welding Issues for Flawless Construction Outcomes

Efficiency and precision are extremely important in the world of welding, where even the smallest imperfection can compromise the structural honesty of a produced item. One common obstacle that welders face is damaging, a problem that can weaken a weld joint and lead to costly rework. By comprehending the source of undercut welding and carrying out reliable techniques to avoid it, welders can boost their craft to brand-new levels of quality (Preventing weld undercut). In the search of flawless construction outcomes, understanding the art of welding to prevent undercut concerns is not simply an ability but a need for those striving for perfection in their work.

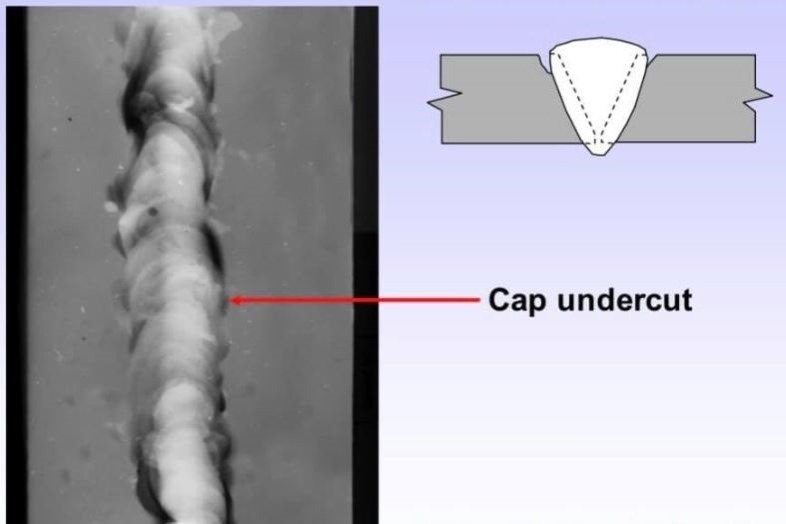

Comprehending Undercut Welding

To prevent undercut welding, welders ought to make sure appropriate welding criteria, such as changing the present, voltage, traveling rate, and preserving the right electrode angle. By recognizing the causes of undercut welding and executing precautionary steps, welders can accomplish premium, structurally sound welds.

Reasons For Undercut in Welding

Recognizing the variables that contribute to damage in welding is necessary for welders to generate high-quality, structurally audio welds. Insufficient welding wrong or existing welding rate can likewise contribute to damage. Understanding these causes and executing appropriate welding techniques can aid protect against undercutting problems, making sure sturdy and solid welds.

Strategies to stop Undercutting

To alleviate the threat of undercutting in welding, welders can use tactical welding techniques intended at improving the quality and honesty of the weld joints. One efficient approach is to change the welding criteria, such as voltage, existing, and take a trip rate, to guarantee appropriate heat input and deposition. Keeping an ideal electrode angle and guaranteeing regular travel rate can likewise help prevent undercut. In addition, using the appropriate welding technique for the particular joint arrangement, such as weave or stringer beads, can add to lowering undercutting. Preventing weld undercut.

Moreover, correct joint prep work, consisting of making sure clean base materials without contaminants and using the proper welding consumables, is important in avoiding undercut problems. Using back-step welding techniques and controlling the weld grain from this source profile can also help disperse warmth uniformly and decrease the threat of undercut. Normal examination of the weld joint throughout and after welding, along with implementing top quality assurance steps, can help in resolving and discovering damaging concerns immediately. By implementing these methods carefully, welders can accomplish flawless construction results with very little undercut defects.

Value of Proper Welding Specifications

Choosing and maintaining proper welding parameters is important for achieving successful welds with minimal defects. Welding specifications refer to variables such as voltage, existing, travel speed, electrode angle, and protecting gas flow rate that straight influence the welding process. These specifications must be meticulously adjusted based upon the kind of material being welded, its density, and the welding technique used.

Correct welding criteria guarantee the correct amount of heat is put on melt the base steels and filler product evenly. If the parameters are established expensive, it can cause extreme warm input, creating spatter, burn-through, or distortion. On the other hand, if the parameters are description also low, insufficient blend, lack of penetration, or damaging might take place.

High Quality Assurance in Welding Workflow

Final Thought

In verdict, grasping the art of welding needs a complete understanding of undercut welding, its reasons, and strategies to avoid it. By making sure proper welding criteria and carrying out quality control techniques, perfect construction results can be achieved. It is crucial for welders to constantly pursue quality in their welding procedures to avoid undercut problems and produce high-grade welds.

Undercut welding, an usual problem in welding procedures, occurs when the weld steel does not appropriately load the groove and leaves a groove or depression along the welded joint.To stop undercut welding, welders ought to guarantee correct welding parameters, such as readjusting the present, voltage, traveling speed, and maintaining the proper electrode angle. Insufficient welding inaccurate or existing welding rate can additionally contribute to undercut.To mitigate the risk of damaging in welding, welders can employ tactical welding methods aimed at boosting the high quality and stability of the weld joints.In conclusion, grasping the art of welding requires a thorough understanding of undercut welding, its causes, and techniques to avoid it.

Report this page